CPGs Wrestle with Workforce

If you follow the packaging industry, whether through news articles, industry periodicals or first hand through direct buyers at CPG companies, one of the largest drivers in packaging is the stress on workforce demands. This can include how difficult it is to find reliable workers that are dedicated to the success of the company. It can also be in the aspect that most of the line operators working the packaging line equipment are not trained properly on that piece of equipment and all of its capabilities.

As the packaging industry tries to modernize technology, not all of their workforce can keep up. As a hot melt equipment manufacturer, one of our core competencies is our knowledgeable technical support. If you have any Universal Systems SE equipment or ProBilt™ machines on your packaging lines, you can rest assured that you will get speedy, knowledgeable sales and technical support. However, in many instances, line operators do not have that type of experience or knowledge base. That can lead to “on the fly” fixes, which usually equates to weakened product and voided warranties. At Universal Systems SE we understand that knowledge is power, and we want to make line operators jobs easier, not harder. With that in mind, we have kept all of the ProBilt™ hot melt application systems uniform and easy to operate. We also try to make our clients smarter when they call with issues, asking questions to help them learn or giving them some simple troubleshooting tips to follow for the future.

In addition to being able to help line operators with questions and knowledge, we also make sure to include in every shipment all of the pertinent manuals and information guidelines needed. For example, if your company is ordering ClearFlow™ heated hoses (Universal Systems SE’s proprietary line of heated hot melt hoses), each shipment will include installation and care instructions. The same goes for our ProBilt™ applicator guns. With the purchase of any ProBilt™ application gun, we include a list of maintenance recommendations on the gun, modules and nozzles.

So, as CPGs continue to have concerns with their workforce, we here at Universal Systems SE we will continue to do everything in our power to ensure that we keep them knowledgeable on our equipment.

To learn more about our ClearFlow™ hoses or any other ProBilt™ products, please reach out to sales@ussefl.com or call (561) 272-5442.

Cost-Effective Manufacturing

As we continue through 2019, it is clear that big brand CPG budgets are getting tighter when it comes to packaging. Larger companies are no longer bleeding money on big brands that offer not much more than a brand name and pretty blue logo. We have often asked ourselves how companies like Nordson® can get away with charging so much for the same quality product that Universal Systems SE manufactures. Especially since those big brands are not even manufacturing in the USA. That trend is starting to change.

As the American economy continues to change, it is clear that companies need an alternative to the brand name big price tags. It all comes down to shopping around for quality manufacturing that can be done in a more cost-effective way. And yes…it can be done. Cost-effective manufacturing should be the main focus of all companies when it comes to packaging their products. Americans no longer care about a name, they care about performance, quality and cost. Just because it is the most expensive thing on the market, doesn’t make it the best or most reliable. And that rings true for packaging manufacturers as well.

Many CPGs are losing the battle for shelf space and margin growth, which is increasing the pressure on suppliers such as packaging manufacturers to decrease costs. With more brands on the shelf and less market share, big CPGs need to start thinking smartly about their packaging solutions. It might not be the best idea to bring in a company like Nordson® to customize a hot melt solution that will cost you an exorbitant amount of money and take 6 months to get, when you can go with a company like Universal Systems SE who has engineers with over 40 years of experience that actually understand what you need because they have pretty much seen it all.

Not only is cost-effective manufacturing a pull in the marketplace, but knowledgeable customer service and support. If your packaging line goes down, it could cost you thousands of dollars a minute. A large brand with an untrained rep isn’t going to be able to get you up and running with a phone call. Universal Systems SE will! Think about that the next time you place an order for a new hot melt system or components.

Whatever you might need for your hot melt machines, we manufacture it at our Florida facility. Whether it is heated hoses, applicators, filters, modules, nozzles, etc. We also can walk you through troubleshooting any issues or help you with customized set ups. Call Universal Systems SE today at (561) 272-5442.

RTD Sensors

RTD Sensors (resistance temperature detectors) are used in hot melt packaging systems because of their precision in sensing and proportioning temperature. They consistently maintain a temperature control stability of +/- 1-degree Fahrenheit. With the ever-increasing price of adhesive, it is important that RTD sensors are used in all of Universal Systems’ hot melt hoses and glue applicators for steady adhesive application. When combined with USSE’s patented AccuScan™ solid-state control system, RTD sensors provide precise bead uniformity for all of our ProBilt™ applicators.

Since RTD sensors are so key to the adhesive application process, it is important to check them first whenever you notice glue inconsistencies. If you see that your glue bead is not sticking properly or getting clogged, it could be caused by inconsistent glue temperature. There are several causes of inconsistent glue temperature. For example, if your tank operators are opening the cover to add glue, that will cause a temperature change. RTDs control that process, by notifying the heater to turn on and run longer when those situations occur. If your RTD is weak, then the heater will not be able to maintain steady temperature. It is the easiest, most overlooked and one of the least expensive components in your application process, but is worth it’s weight in glue!

When it comes to understanding the components that make up your adhesive application system, we believe that knowledge is power. So, if you have any questions, or think that you may be having issues with your RTD sensor, do not hesitate to call Universal Systems at (800) 848-5018 to speak with one of our technicians. We can walk your line operator through testing RTD sensors and how to switch them out correctly and safely.

The Importance of Using Aluminum for Manifolds

Universal Systems SE manufactures high quality hot melt application manifolds that will work with most all hot melt application systems. We understand the importance of durability, consistency and effectiveness in packaging manufacturing, which is why we use 6061T aluminum when making all of our manifolds.

What is a Manifold?

When evaluating what you need for your hot melt application system, it is important to understand each item that makes up the application gun. The manifold is the aluminum gun body, that houses the heater & sensor, and is where the modules mount.

Why do we use Aluminum?

Aluminum is used on all of our hot melt applicator manifolds because it is an excellent conductor of heat and dissipates heat very efficiently. Aluminum also has a very high strength to weight ratio, meaning that although it is light-weight, it is extremely strong. Its strength is what allows for peak performance during the rigorous packaging process. It is also non-toxic, cannot burn and is easily recyclable.

Why do we use 6061T Aluminum?

All of Universal System’s ProBilt™ manifolds are manufactured using 6061T aluminum. 6061T aluminum is aviation aluminum and used for the building of all jet aircrafts. This will extend the lifespan and durability of the manifold and increase it’s on the floor performance.

For more information on how to buy a hot melt gun applicator or manifold, please reach out to sales@ussefl.com or call (561) 272-5442 today!

Zero Cavity Modules and What They Are Used For

There are several different set ups available for your hot melt application. That’s because not all industries use glue application for the same reason. The most common form of hot glue application is standard case packers for mass production high speed packaging. Typically, those lines use standard H200 modules. However, glue application is used to seal other, more specific products. For example, swirl pattern modules are used for glue application on feminine hygiene products, diapers and also for sealing air filters. This blog is going to specifically explain zero cavity modules and what industries use them and why.

Zero cavity modules have a very specific look, with a nozzle head attachment rather than a screw on nozzle. They also come with an E-Z Micro Adjust attachment to manage precision glue application. This nozzle & micro-adjust feature is custom manufactured for precise glue placement on smaller boxes, such as crayon boxes or pharmaceutical products. This unique technology allows for line operators to place a small amount of glue on a small, predetermined location without creating any stringing. Typically, because of this precise requirement, most zero cavity modules are made with either a .008 or a .012 diameter orifice, so that there can never be too much glue applied.

Because zero cavities have a matched piston needle and seat, when they finally wear out, most manufacturers require customers to replace the entire module. Universal Systems does not. We manufacture a rebuild kit specifically for zero cavity modules for a fraction of the price of replacing an entire module. Check out our rebuild kits here: https://www.ussefl.com/products/hot-melt-modules/module-rebuild-kits/.

Not many hot melt application manufacturers offer zero-cavity modules. Luckily, here at Universal Systems we have been manufacturing this specific module for over 25 years. If you would like to learn more about zero cavity modules or get a price quote, please reach out to sales@ussefl.com or call (561) 272-5442.

How to Keep Old Melters Operable

Do you have an old series 2300 or 3000 melter that you are still using but need to find parts for? If you do, your packaging line is running a melter that is 15 – 20 years old. That means that your line operators are maintaining your packaging lines well and spending money in the right areas to keep efficiency and durability a priority. With that said, not everything will last forever. While you can probably keep the control panels of the 2300 or 3000 melter, some of the internal and exterior parts may need to be replaced. The reality is that Nordson® no longer supports these tanks. However, Universal Systems SE does. Universal Systems SE manufactures pumps, filters, hoses, guns, modules and nozzles that are compatible with your old melters.

Pneumatic Pumps

The first thing to go on your old melter, will most likely be your pump. Once that stops working, it will become very clear that your OEM no longer manufactures replacements for that part. So now you have to decide between purchasing a new melter from them for $15,000+, or trying to replace your pump. Universal Systems SE manufactures new series 2300 and 3000 pumps for a fraction of the price of a new Nordson® melter. Check out our full line of pneumatic pumps.

Actuator

If you have experience with rebuilding pumps, Universal Systems also manufactures the pump shifter and fork for the ProBilt™ series 2300 and 3000 pumps. This is another item you will not be able to find with the OEM because it has been discontinued.

Tank Filters

Since your series 2300 or 3000 melters have been operating on the line for so many years, your line operators probably change out the tank filters frequently. As the years have gone by, you may find it more difficult to find reasonably priced, or readily available tank filters. Universal Systems manufactures the tank filter assemblies, filter cores and filter screens to fit your series 2300 and 3000 melters.

Same Footprint

If you have gone through all of the steps to fix the problem with your old melter and find out that it is the control panel, which has been discontinued, Universal Systems SE has a solution for that as well. Our ProBilt™ melters have the same footprint and dimensions as your current series 2300 or 3000 melter. That means that your NEW ProBilt™ melter, that comes with a 10-year heater warranty, will fit right in where your old melter comes out.

For more information or to contact a technician that can help you troubleshoot issues with your old melter, call (561) 272-5442 or email sales@ussefl.com.

Managing Your Glue Usage in Packaging

Hot melt adhesive is not cheap and you may notice that the prices are only going up. What purchasing agents might not know, is that a lot of packaging lines are using more glue than is actually needed. There are a few simple ways to manage your actual glue usage and help cut costs to manage your budget.

Nozzle Diameter

The first step in managing your glue usage, is knowing the diameter nozzle tip you are using in your packaging lines, and understanding why you are purchasing that size. A lot of times, our sales reps will get calls from customers that want to buy larger size nozzle tips because their line operators are saying there is not enough glue being released on the cartons. Obviously, as you increase your nozzle tip diameter, the more glue you are going to use overall and increase your yearly costs for adhesive. This can also cause several other issues, such as potential sealing issues if the hot adhesive does not have enough time to dry as it moves along the cartoner. If your line operators are asking for larger diameter nozzles, question them as to why.

Evaluate Set-up

If your line operators are stating that the glue is not keeping the packaging closed, which is why they need larger nozzles, evaluate your setup. Check the distance your gun applicator is to your carton and at what temperature you are heating your adhesive. If the adhesive is not hot enough and your gun is too far away from the application site, the adhesive could be cooling before it even hits the carton which is why it is not creating a tight seal. Simply increasing your heating temperature or moving your gun applicator closer to the end application site could solve this issue. You could also be putting down too much glue already. If you have a high-speed packaging line, and put down too much glue, the speed will not allow time for the large amount of glue to dry.

Change Your Filters

Another simple solution to managing your glue usage, is to check both your tank and gun filters. If your nozzles are clogging frequently, causing the line operators to buy larger diameter nozzles, they may be clogging due to char. Char is a typical occurrence in hot melt packaging, but the transfer of most char can be prevented by regularly changing your tank and gun filters. These filters will extend the life of both your modules and nozzles.

For more information or tips on how to increase your packaging line efficiency and lower your costs, call a Universal Systems representative at (561) 272-5442 or email us at sales@ussefl.com.

The Importance of Utilizing Cross-Referencing

The packaging industry is entering the time of year when budgets are getting tight, but replacement parts are still needed. Universal Systems SE will cross-reference any of our competitor item numbers and get you high quality replacements. Cross-referencing Nordson item numbers to Universal Systems SE item numbers will help to lower your cost and keep your packaging lines running longer!

You will also notice that our competitors change their part number often. This is why we offer the search bar on our website for any cross-reference numbers you might have. Some of the most common cross references are listed below. If you purchase any of the parts listed on a regular basis, please feel free to call us today! We guarantee that all of our products are quality control tested before leaving our facility and we stand by all of our products with strong warranties.

Adhesive Systems:

P10, 1022234, 1022235, 276881, 276882, 276883, 276884, 276885, 276886, 276033, 276034, 238310, 243666, 168204, 166535 à ALL of these item numbers match USSE # D100-644

Heated Hoses:

4 Ft. Hose:

107288, 129556, 100120, 274791, 276151 –> 4104

6 Ft. Hose:

107286, 129557, 100121, 274792, 276152 –> 4106

8 Ft. Hose:

107287, 129559, 100122, 274793, 276153 –> 4108

10 Ft. Hose:

107289, 129561, 100123, 274794, 276154 –> 4110

12 Ft. Hose:

107310, 129562, 100124, 274795, 276155 –> 4112

16 Ft. Hose:

104008, 129564, 100125, 274796, 276156 –> 4116

20 Ft. Hose:

223838, 223836 –> 4120

24 Ft. Hose:

129565, 100832, 100126, 274797 –> 4124

Applicator Guns:

H200 1 Module AO/AC

8503717, 8505756, 8505768 –> 39105

H200 1 Module (AO/SC)

274596, 224939, 8503591, 8503686 –> 39107

Modules:

H200 (AO/AC)

1052927 –> 29215

H200 (AO/SC)

272282, 276119, 326583, 331979, 1048115, 2210, 2219, 2400, 2410 –> 29219

For any other questions on cross-referencing, please call (561) 272-5442 or email sales@ussefl.com.

In-Line Gun Filters

There are a couple different types of filters that you need to change out regularly on your adhesive melter system. One is a tank filter, which we describe in a previous article: The Importance of Tank Filters. The second, is the in-line gun filter. This is the filter that goes between the hot melt gun applicator and heated hose. This is the last line of defense against char being transferred through the module and potentially clogging the nozzle.

There are a three different in-line filter assemblies that are available for your hot melt system: Straight, 45 Degree & 90 Degree. The first is a filter assembly with a straight connector from the gun to the hose. This straight fitting is used when guns line up directly with hoses, typically applying the glue straight out to onto the boxes. The other two filter assemblies offer a 45 degree and 90 degree fitting that allows you to connect the hose to the gun at an angle. These filter assemblies are mostly used on setups where the applicator guns are either above or below the packaging line.

Each filter assembly is available with 50 mesh, 100 mesh and 200 mesh filters. The replacement filters are sold separately in packs of 5 for easy installation so that you do not need to switch out the entire assembly. The filter is easily screwed into the top of the filter body as seen below. Please make sure that you lubricate the o-rings before installation to help you for future filter changes.

For more information on which in-line filter assembly is best for you, please call (561) 272-5442 or email sales@ussefl.com.

Line Operators: The First Line of Defense

Understanding hot melt tank systems is no simple task. It usually takes years of experience to learn how to effectively manage adhesive systems and keep your packaging line running efficiently and effectively. Universal Systems SE understands that new line operators come into work and might need help learning which items to replace and how to replace them the correct way. That is why we offer technical support to all of our ProBilt™ customers!

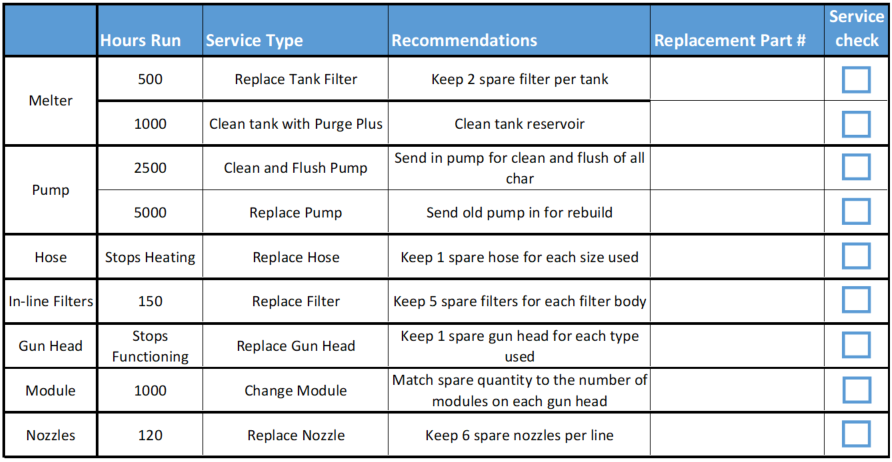

There are several maintenance tasks that we recommend be completed on a regular basis to keep your adhesive system free of char and debris, which is the number one culprit in bringing down a line. Below is an easy maintenance checklist that each line operator should have in hand.

We recommend that you print this checklist out and give it to every shift that operates the packaging line. Keep in mind that changing out items such as gun heads, modules, filters and pumps all require you to clear the old lines and remove the air pressure before re-installation. Releasing the air pressure and removing all old adhesive will ensure that all seals stay intact and reduces the char transferred from the old to the new parts.

If you need help changing out parts or have questions about which items need to be changed regularly, please call (561) 272-5442 or email sales@ussefl.com.