Simplify with the AccuScan™ Control Panel

Universal Systems SE manufactures a premiere line of hot melt adhesive systems. Our ProBilt™ line of tanks all come with our patented AccuScan™ Control Panel. The AccuScan™ Control Panel is exclusive to ProBilt™ machines and is easy for any line operator to use.

One of the most common feedback points we hear from customers is that they like simplified operational equipment. Usually line operators are understaffed and overworked. Simplifying how they use our equipment is a big selling point and the AccScan™ Control Panel is a great example of that.

Universal Systems SE developed our AccuScan™ Control Panel to simplify the operation of our adhesive melter systems. The main control screen lists the operational settings for up to 4 hoses and guns and the main tank. You can filter through these sections by pressing the Zone button. Once you choose the zone you wish to set the temperature for, press and hold the Set button. Then, using the up arrow, the digital screen will show the temperature setting increase until you reach your desired temperature setting. Once the tank or hose zones are set to desired temperatures, release the Set button. We also offer a Set Back button on the main screen. The Set Back feature puts the machine in an idle state, heating only to 165 degrees.

For further step by step instructions, we have put a video on our Universal Systems SE YouTube channel. Please check it out at https://youtu.be/QhSCXZs-8wY.

For any further instructions or information about our AccuScan™ Control Panel please call (561) 272-5442 or email sales@ussefl.com.

Melt Rate vs. Pump Rate

When purchasing a hot melt adhesive system, it is important to know your desired melt rate and pump rate. It is also important to understand the difference.

All Universal Systems SE ProBilt™ tanks are equipped with a 14:1 ratio pneumatic pump assembly. Pneumatic pumps are most common and have a maximum pump rate of 75 lbs. per hour. No matter what the tank capacity is, whether it is 12 lb., 15 ob., or 20 lb., the pump will max out at 75 lbs. If you need to pump more adhesive then that per hour, you will need to transition to a gear pump system with a larger tank capacity.

The melt rate is the rate at which the tank will melt the adhesive you put into the reservoir. This is where the tank capacity comes into play. Before moving forward with any hot melt adhesive system, first you need to understand how many pounds you need to melt per hour. The melt rate is dependent on how many hoses and gun applicators you are running and how many boxes are sealed per minute on your packaging line. The most common tank capacity is the 20 lb. (10 Liter) ProBilt™ 20, with a melt rate of 23 lbs. per hour. If you are only running one line with one hose and gun applicator, then you may only need the 15 lb. (7 Liter) Probilt™ 15 which melts 18 lbs. per hour.

A common misconception is that the on-demand autofill system, the ProBilt™ Phoenix, will have a larger melt rate and pump rate. That is incorrect. The tank capacity on any auto fill system is the same as a regular tank such as the ProBilt™ 20. However, the advantage to the auto fill is that the line operators will not have to watch the adhesive level in the tank as closely. The vacuum system connected to the tank will sense when the adhesive level is low and automatically fill the tank. This helps eliminate dry running and pumps will last longer. However, the pump rate on this system will still max out at 75 lbs. per hour.

For additional information about melt rate and pump rate on all of our ProBilt™ tanks, please call (561) 272-5442 or email sales@ussefl.com.

Line Operators: The First Line of Defense

Understanding hot melt tank systems is no simple task. It usually takes years of experience to learn how to effectively manage adhesive systems and keep your packaging line running efficiently and effectively. Universal Systems SE understands that new line operators come into work and might need help learning which items to replace and how to replace them the correct way. That is why we offer technical support to all of our ProBilt™ customers!

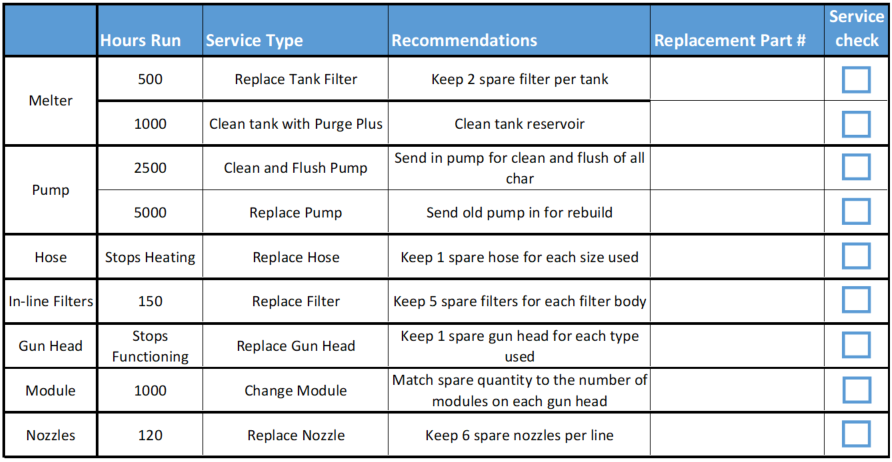

There are several maintenance tasks that we recommend be completed on a regular basis to keep your adhesive system free of char and debris, which is the number one culprit in bringing down a line. Below is an easy maintenance checklist that each line operator should have in hand.

We recommend that you print this checklist out and give it to every shift that operates the packaging line. Keep in mind that changing out items such as gun heads, modules, filters and pumps all require you to clear the old lines and remove the air pressure before re-installation. Releasing the air pressure and removing all old adhesive will ensure that all seals stay intact and reduces the char transferred from the old to the new parts.

If you need help changing out parts or have questions about which items need to be changed regularly, please call (561) 272-5442 or email sales@ussefl.com.

How to Prevent Your Glue from Stringing

One of the most common issues that many packaging line operators experience with their adhesive melter is stringing. Stringing is when the adhesive is applied to the box, but before the flaps are closed on the cartoner, the glue starts to dry and string like cotton candy floating through the air.

There are a couple of fixes for this issue. Whether you are using a straight, right angle or swirl pattern nozzle, try moving the applicator gun closer to the box flap where you are applying the adhesive. The stringing could be caused because it is travelling too far of a distance from the applicator gun to the box. The shock from hitting the cooler factory air could be causing it to lose viscosity and start drying before it even hits the box. Not only will that cause stringing, that might also compromise the integrity of the glue hold on your product packaging.

Another cause of stringing glue could be temperature. Every adhesive is different and each one might require a different melt temperature. In order to keep the adhesive a consistent viscosity, make sure that the temperature on your glue tank and applicator guns are set correctly per the adhesive requirements. If the adhesive is too viscous then you might need to increase the tank temperature or change to an adhesive with a lower viscosity. If your tank temperature is correct, but your guns are not hot enough, then the glue could start to cool while travelling from the tank to the applicator gun. In this scenario, you would see that the thickness of the glue as it leaves the nozzle. Some line operators might try fixing the issue by putting a larger diameter nozzle on the module, which could be a temporary fix, but the real issue could be the temperature setting on the gun. Simply increase the gun temperature as needed to ensure a smooth, consistent adhesive flow.

There could also be an issue with the adhesive you are using on your packaging line. Like many products, if the adhesive is too old, has been sitting for too long, or has been heated and cooled too many times, this could cause stringing. We recommend that you drain all old adhesive from your tank, clean the tank with a cleaner such as Purge Plus™, and refill with fresh adhesive.

Universal Systems SE recommends trying to correct stringing if it is happening to your packaging line. Some line operators may think it is not that big of an issue, or they might blame the adhesive manufacturers, when in fact it could be a simple and important fix.

For more information or technical support to help you better understand how to fix your stringing glue, please call Universal Systems SE at (561) 272-5442 or email sales@ussefl.com.

What Diameter Nozzle Should You Use?

Hot melt adhesive application nozzles, or nozzle tips as they are commonly called, are the component that apply the glue onto boxes in packaging lines. Universal Systems nozzles are made out of brass with stainless steel tips to withstanding any beating they might take from box flaps in the packaging line.

Nozzles comes in many shapes and sizes, and are usually the part on the adhesive system that is most experimented with. Most nozzles are easily changed out by simply unscrewing them from the module. Other nozzles, like the ones on reduced cavity, zero cavity and ProBead modules are called integrated nozzles. We sell replacement nozzle kits for integrated nozzles that include the nozzle tip, needle, brass needle guide and installation tool.

The diameter of the nozzle tip determines the amount of adhesive that is distributed onto the box flap. Because you can easily switch them out, most line operators experiment with diameter to enhance productivity. For example, smaller, more precise glue application will require a smaller diameter nozzle. Larger, faster cartoners, will most likely run larger diameter nozzles to distribute a greater amount of glue and quickly seal boxes. Keep in mind that the larger the diameter nozzle, the more adhesive your tank will process. So make sure that your line operators are keeping a close eye on the adhesive level in the tanks. Dry running a machine can compromise your pump and create a costlier repair.

Because most adhesive systems run 24/7, the nozzle is the most commonly clogged component on your line. This is due to char or debris travelling from the tank, through the hose, into the gun and through the module. Because the nozzle is the smallest orifice on your system, most char will get stuck and you will be unable to get a consistent adhesive flow. Universal Systems SE offers nozzle cleaning kits that you can purchase instead of replacing nozzles. However, most line operators find the cleaning of nozzles a tedious process, even though when done correctly it works. Nozzle cleaning kits can save you money in the long run on replacing nozzles.

Another important aspect of nozzle diameter correlates to the size of the mesh in-line filter used on your system. The larger the diameter nozzle, the lower number mesh you should use. The smaller the diameter nozzle, the finer mesh you should use. For example, with a .024 diameter nozzle, you should have a 50 mesh filter size. With a .012 diameter nozzle, you should use 200 mesh filters.

For more information about what diameter nozzle you should be using, call (561) 272-5442 or email sales@ussefl.com.

Low Profile Glue Guns

Low profile guns are one of the most commonly used gun on cartoners. They come in two module and four module versions to allow for easy glue distribution on small to large box sizes. Their name comes from their unique gun body design which is angled on each side. The angled design sides allow for the box flaps to flawlessly close while the gun is applying the adhesive on to the boxes.

Even though the low profile guns look different than a standard gun applicator, they use standard H200 modules. This allows you to use the same modules and nozzles that you run on all of your other types of glue gun applicators. With both our two module and four module low profile gun, the modules are set with .88 inch centers and are a air-open, spring-close. The most commonly used nozzles for low profile guns are one or two orifice, right angle nozzles.

A few of our customers have asked over the years if Universal Systems SE manufactures a one module low profile gun. The answer would be no, however we can insert a custom module blank to the two module low profile gun, effectively turning it into a one module applicator. An advantage to this is that our custom module blank is removable, in case you ever change up your packaging line and need a two module low profile gun.

The item numbers for our Universal Systems SE ProBilt™ low profile gun heads are item # 3281 for the two module version and item # 3471 for the four module version. If you are interested in learning if your packaging line runs low profile guns compared to standard glue applicators, or the advantages to switching to a low profile gun, please call (561) 272-5442 or email sales@ussefl.com.

Custom Manifolds & Gun Applicators

There are not many manufacturers in the hot melt industry that have the ability to work with clients and create custom manifolds and gun applicators to fit their unique needs. Universal Systems SE has that ability and is willing to pair up our engineers with our client’s team to ensure that we manufacture the exact applicator needed for any job.

Over the last forty years, Universal Systems SE has manufactured an array of different custom manifolds and gun applicator systems for different types of industries. Not only can our custom gun manifolds distribute adhesive onto boxes in packaging lines, but they can be used for distributing make-up, candle gel, etc. Depending on the viscosity and melt rate of the substance needed to make the transfer, our custom manifolds and applicators will work with several different types of materials.

The custom manifold and gun process is simple. Contact one of Universal Systems SE’s customer service representatives, by either calling in to (561) 272-5442 or submitting a custom gun online form. You will then be connected with a USSE mechanical engineer. After all of the client’s needs are communicated with our engineering team and all questions answered, USSE will provide the customer with a custom manifold drawing for approval. The drawing will include dimensions of the manifold, spacing of modules, type of modules and all cordsets that are included and the location of those cordsets. Once the drawing is signed off on by the customer, we then manufacture the manifold body. After a vigorous quality control process, each custom manifold is inspected and tested to ensure all dimensions are correct and that the custom gun matches the approved drawing. Once the manifold passes all initial testing, modules are added and the custom gun is created and tested internally by two different QC Engineers. Once there is approval by both engineers, the final product is cleaned and ready for shipping.

The normal process for custom manufactured manifolds and completed guns is four to six weeks, with extra time potentially added in depending on customer turnaround time for drawing approvals.

If you are interested in learning more about the types of custom manifolds and gun applicators that Universal Systems SE can engineer for you, please call (561) 272-5442 or email sales@ussefl.com.

What is Old is New Again

Every year, some hot new product comes out and promises you the world. Then, when you get it, you realize that the “latest technology” is more frustrating and causes more trouble than it’s worth. Not only does it cost you more money initially, the maintenance and unreliability seem to also increase. The same thing has happened with some of the largest hot melt manufacturers. Their latest technology that has been implemented in all of their new systems to make your line operator’s life easier, can potentially make it harder and more expensive.

Which is why Universal Systems SE is dedicated to keeping our current high standard of precision engineering, but with our existing look and ease-of-use technology. Universal Systems SE is standing behind our current key attributes: reliability, long life span, economical pricing and simple but effective operation. Why add more bells and whistles when the current tried and true works just fine.

Tried and True ProBilt® Product Features:

10-year tank warranty.

User-friendly design for easy installation, simplistic operation, and minimal maintenance.

AccuScan Control System with on board microprocessor and keypad controls for melter, heated hoses and adhesive applicators.

“One touch” setback key for standby mode.

Parent machine interfacing.

External fault alarm interfacing.

Under temperature and over temperature protection on all zones.

Faults trigger both visual indicators as well as an audible alarm.

RTD temperature control with self-diagnostic digital temperature readings within +/- 1 degree.

LCD display for both temperature and system status.

Teflon® coated tank.

Stainless steel and high strength aluminum construction allows easy cleaning and unequaled durability.

14:1 ratio balanced pneumatic piston pump.

Self-sealing, full opening lids for easy loading and maintenance.

For more information on Universal Systems SE’s line of ProBilt® products, please call (800) 848-5018 or email sales@ussefl.com.

A Class Above the Rest

There are five main components that should go into your search for the right hot melt equipment manufacturer: Innovation, Knowledge, Quality, Price & Compatibility. Universal Systems SE has made it our top priority, over the last four decades, to ensure our customers get all of these. We do not compromise price for service and we stand behind all of our equipment with the strongest warranty program in the industry.

Innovation

Universal Systems SE has just launched our latest product in the ProBilt Series: The ProBilt Phoneix. This on-demand melter system allows packagers to melt and use adhesive only when they need it. The adhesive storage container eliminates the need to manually fill the melter tank, reducing adhesive spillage and waste, while improving safety. Our state of the art adhesive sensor and innovative vacuum technology will automatically fill your tank with adhesive to your desired level.

Universal Systems SE also manufactures 8 lb., 12 lb., 15 lb., 20 lb. and 40 lb. tanks that are the same footprint as most Nordson melters on the market. Our ProBilt systems continue to lead the industry with minimal down-time, easy to operate components and consumer flexibility.

Knowledge

When researching manufacturers to partner with, knowledge and availability are key. Our technicians have over 40 years’ experience in the hot melt industry and can help solve almost every issue you might run in to, because we have seen it all! Universal Systems SE’s facility is located in the United States and we are available for service calls, even if it’s a video conference to walk through any issues you might be experiencing.

Warranty, Price, Compatibility

We stand behind all of our products 100%, which is why we offer the longest warranty in the industry on our ProBilt tanks, 10 years! Also, if you find a cheaper rate from another direct manufacturer, which we are confident you won’t, we will match that price! Whether the pricing is from Nordson, Graco, ITW Dynatec or Robatech. We also ensure that almost all of our equipment is Nordson compatible. This means that even if you bought your main hot melt machine from Nordson you don’t have to stay with them forever. Even if your Nordson melter has been discontinued, such as the 2300 or 300 Series, you can still buy all of your replacement parts from USSE. We will warranty all parts that you buy from us, even if they are being paired with a competitor part.

For more information on Universal Systems SE or the ProBilt Series, please contact us at (561) 272-5442 or email us at sales@ussefl.com.

The Purpose of Cartridge Heaters

The purpose of a cartridge heater is the heat metal parts by inserting them into predetermined spaces of the parts. The most common use of cartridge heaters in the hot melt industry, is for heating all automatic applicators, all hand guns, and sometimes even melters. They are very easy to install as the heaters are made slightly undersized relative to their nominal diameter.

It is recommended that the watt density of a cartridge heater only be as high as needed. Under normal applications maximum watt density is not required. Safety margins usually are rated by using less than the maximum allowed. Rather than having the highest possible wattage per heater, heaters should be selected that give a more even heat pattern.

In the hot melt equipment industry, watt densities are usually high rather than medium. In machining the applicators that receive the heaters, holes are drilled and reamed to exact tolerances. In a high watt density application, a very close fit is important. This style cartridge heater should have a hole tolerance of plus or minus .003. After holes have been properly drilled and reamed they should be cleaned and degreased to remove any remaining cutting debris.

Watt density is the heat flow rate or surface loading of a cartridge heater. It is the number of watts per square inch of a heated surface area. Watt density calculation would be as follows.

Watt Density = wattage / (pi x diameter x heated length)

The heater cartridges in hot melt systems and their components are normally controlled by a master temperature controller on the hot melt units themselves. The temperature controllers on the hot melt units read RTD sensors to control the temperature of the heaters. RTD sensors are found in all components of a hot melt system including the tank, the heated hoses, and all heated applicators.

To find out more about our cartridge heaters please visit our website at www.universalsystemsse.com or call us at (561) 272-5442 or email us at sales@ussefl.com.