Keep Your Melter Clean

Keeping your hot melt adhesive system clean may seem like an impossible task. Take a look at your melter now, it is probably bronzed and blackened with old melted glue. Well guess what…that is what travels through your application system and onto your boxes. Also, do you see all of the little bits of blackened glue? That is called char, and it is a big problem for your equipment. Even though your melter looks like this now, it is possible to keep it clean “ish”. Now, this melter runs in a packaging line, most likely 8 – 12 hours per day, every day, so there is no way that tit is going to stay pristine or even look clean after its first use. However, there are a few tricks of the trade to keep your melter looking good and running even better for decades to come.

Universal Systems SE sells a product called Purge Plus™ that, when used properly, will clean almost any melter. The directions for use are simple:

- Drain all hot melt from tank reservoir

- Fill reservoir with Purge Plus™

- Heat Purge Plus to 350°F – 375°F for approximately 45 minutes

- Open tank drain valve and remove tank filter assembly

- Slowly start pump and run Purge Plus™ through the tank manifold and into a meal container until reservoir is empty

- Stop pump, replace filter assembly and close drain valve

- Carefully wipe any remaining contaminants from tank reservoir

- Add new hot melt and recirculate through system

- Drain one cup from each hose

In addition to cleaning the tank reservoir and heated hot melt hoses, if you are running a ProBilt™ series melter, the exterior is manufactured out of 316 grade stainless steel. So, any stainless steel cleaner will shine the exterior of the tank.

For any additional questions about Purge Plus or how to properly clean your tank and hoses, please call a Universal Systems service technician at (561) 272-5442 or email tech@ussefl.com.

Hunting Down Old Adhesive Melter Parts

An interesting fact about the packaging industry that most people don’t realize, is that purchasing agents become avid internet hunters when it comes to finding parts for their old equipment. There are several resources out there, the largest being eBay, for purchasing agents to find and buy parts for their old adhesive melters. The problem is, when buying from a bid platform, you never know what you are going to get. If you are looking for an old part, for a melter that is more than 20 years old, the part you find online could either be used or the wrong part. Also, with most online bid platforms, you get what you get. There are no returns or exchanges for your actual part. And in most cases, you get what you pay for.

Universal Systems SE realizes how important it is to be an online resource of purchasing agents, which is why we have invested in becoming “searchable”. In the last couple of years, we have launched a new website, added more products, and increased the number of cross-reference IDs on our website. We have added pictures, spec sheets and custom contact forms to help purchasing agents get exactly what they need. We are also working on making sure that we show up in the search results when purchasing agents Google old part numbers or manufacturers.

The benefit of buying from USSE is that all of our equipment is new, in stock and you can talk with a technician to make sure it will fit with your current equipment. Another key aspect of working with USSE is our staff of knowledgeable engineers that have been around adhesive melters and packaging line equipment for over 40 years. If you have a question about your old melter, we are most likely the only company in the industry that can answer it.

To test out the knowledge of our technicians, give us a call at (800) 848-5018. We are certain we can get your old equipment back up and running in record time.

CPGs Wrestle with Workforce

If you follow the packaging industry, whether through news articles, industry periodicals or first hand through direct buyers at CPG companies, one of the largest drivers in packaging is the stress on workforce demands. This can include how difficult it is to find reliable workers that are dedicated to the success of the company. It can also be in the aspect that most of the line operators working the packaging line equipment are not trained properly on that piece of equipment and all of its capabilities.

As the packaging industry tries to modernize technology, not all of their workforce can keep up. As a hot melt equipment manufacturer, one of our core competencies is our knowledgeable technical support. If you have any Universal Systems SE equipment or ProBilt™ machines on your packaging lines, you can rest assured that you will get speedy, knowledgeable sales and technical support. However, in many instances, line operators do not have that type of experience or knowledge base. That can lead to “on the fly” fixes, which usually equates to weakened product and voided warranties. At Universal Systems SE we understand that knowledge is power, and we want to make line operators jobs easier, not harder. With that in mind, we have kept all of the ProBilt™ hot melt application systems uniform and easy to operate. We also try to make our clients smarter when they call with issues, asking questions to help them learn or giving them some simple troubleshooting tips to follow for the future.

In addition to being able to help line operators with questions and knowledge, we also make sure to include in every shipment all of the pertinent manuals and information guidelines needed. For example, if your company is ordering ClearFlow™ heated hoses (Universal Systems SE’s proprietary line of heated hot melt hoses), each shipment will include installation and care instructions. The same goes for our ProBilt™ applicator guns. With the purchase of any ProBilt™ application gun, we include a list of maintenance recommendations on the gun, modules and nozzles.

So, as CPGs continue to have concerns with their workforce, we here at Universal Systems SE we will continue to do everything in our power to ensure that we keep them knowledgeable on our equipment.

To learn more about our ClearFlow™ hoses or any other ProBilt™ products, please reach out to sales@ussefl.com or call (561) 272-5442.

Managing Your Glue Usage in Packaging

Hot melt adhesive is not cheap and you may notice that the prices are only going up. What purchasing agents might not know, is that a lot of packaging lines are using more glue than is actually needed. There are a few simple ways to manage your actual glue usage and help cut costs to manage your budget.

Nozzle Diameter

The first step in managing your glue usage, is knowing the diameter nozzle tip you are using in your packaging lines, and understanding why you are purchasing that size. A lot of times, our sales reps will get calls from customers that want to buy larger size nozzle tips because their line operators are saying there is not enough glue being released on the cartons. Obviously, as you increase your nozzle tip diameter, the more glue you are going to use overall and increase your yearly costs for adhesive. This can also cause several other issues, such as potential sealing issues if the hot adhesive does not have enough time to dry as it moves along the cartoner. If your line operators are asking for larger diameter nozzles, question them as to why.

Evaluate Set-up

If your line operators are stating that the glue is not keeping the packaging closed, which is why they need larger nozzles, evaluate your setup. Check the distance your gun applicator is to your carton and at what temperature you are heating your adhesive. If the adhesive is not hot enough and your gun is too far away from the application site, the adhesive could be cooling before it even hits the carton which is why it is not creating a tight seal. Simply increasing your heating temperature or moving your gun applicator closer to the end application site could solve this issue. You could also be putting down too much glue already. If you have a high-speed packaging line, and put down too much glue, the speed will not allow time for the large amount of glue to dry.

Change Your Filters

Another simple solution to managing your glue usage, is to check both your tank and gun filters. If your nozzles are clogging frequently, causing the line operators to buy larger diameter nozzles, they may be clogging due to char. Char is a typical occurrence in hot melt packaging, but the transfer of most char can be prevented by regularly changing your tank and gun filters. These filters will extend the life of both your modules and nozzles.

For more information or tips on how to increase your packaging line efficiency and lower your costs, call a Universal Systems representative at (561) 272-5442 or email us at sales@ussefl.com.

The Importance of Utilizing Cross-Referencing

The packaging industry is entering the time of year when budgets are getting tight, but replacement parts are still needed. Universal Systems SE will cross-reference any of our competitor item numbers and get you high quality replacements. Cross-referencing Nordson item numbers to Universal Systems SE item numbers will help to lower your cost and keep your packaging lines running longer!

You will also notice that our competitors change their part number often. This is why we offer the search bar on our website for any cross-reference numbers you might have. Some of the most common cross references are listed below. If you purchase any of the parts listed on a regular basis, please feel free to call us today! We guarantee that all of our products are quality control tested before leaving our facility and we stand by all of our products with strong warranties.

Adhesive Systems:

P10, 1022234, 1022235, 276881, 276882, 276883, 276884, 276885, 276886, 276033, 276034, 238310, 243666, 168204, 166535 à ALL of these item numbers match USSE # D100-644

Heated Hoses:

4 Ft. Hose:

107288, 129556, 100120, 274791, 276151 –> 4104

6 Ft. Hose:

107286, 129557, 100121, 274792, 276152 –> 4106

8 Ft. Hose:

107287, 129559, 100122, 274793, 276153 –> 4108

10 Ft. Hose:

107289, 129561, 100123, 274794, 276154 –> 4110

12 Ft. Hose:

107310, 129562, 100124, 274795, 276155 –> 4112

16 Ft. Hose:

104008, 129564, 100125, 274796, 276156 –> 4116

20 Ft. Hose:

223838, 223836 –> 4120

24 Ft. Hose:

129565, 100832, 100126, 274797 –> 4124

Applicator Guns:

H200 1 Module AO/AC

8503717, 8505756, 8505768 –> 39105

H200 1 Module (AO/SC)

274596, 224939, 8503591, 8503686 –> 39107

Modules:

H200 (AO/AC)

1052927 –> 29215

H200 (AO/SC)

272282, 276119, 326583, 331979, 1048115, 2210, 2219, 2400, 2410 –> 29219

For any other questions on cross-referencing, please call (561) 272-5442 or email sales@ussefl.com.

Line Operators: The First Line of Defense

Understanding hot melt tank systems is no simple task. It usually takes years of experience to learn how to effectively manage adhesive systems and keep your packaging line running efficiently and effectively. Universal Systems SE understands that new line operators come into work and might need help learning which items to replace and how to replace them the correct way. That is why we offer technical support to all of our ProBilt™ customers!

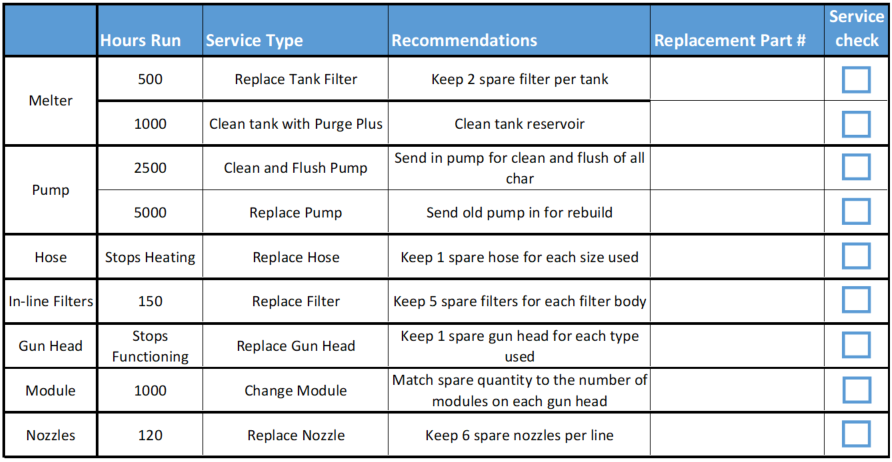

There are several maintenance tasks that we recommend be completed on a regular basis to keep your adhesive system free of char and debris, which is the number one culprit in bringing down a line. Below is an easy maintenance checklist that each line operator should have in hand.

We recommend that you print this checklist out and give it to every shift that operates the packaging line. Keep in mind that changing out items such as gun heads, modules, filters and pumps all require you to clear the old lines and remove the air pressure before re-installation. Releasing the air pressure and removing all old adhesive will ensure that all seals stay intact and reduces the char transferred from the old to the new parts.

If you need help changing out parts or have questions about which items need to be changed regularly, please call (561) 272-5442 or email sales@ussefl.com.

Piston Pump Troubleshooting

There are several things that can cause a piston pump to stop working. The most common reason is that it is clogged. Unfortunately, not all line operators take the time to close the lid on a glue tank. With a lot of carton dust in the air at any facility, this dust gets into the glue pot and melts in with the glue. When the pump shifter runs to pump the glue from the pot into the hose, that carton dust gathers around the pump which can cause it to seize. The simple solution to this is to make sure that all shift line operators are diligent about closing the tank covers, that’s why they are on there.

If carton dust is not your issue, and the pump fails, below are a few other possible causes and the corresponding solutions.

- Adhesive not sufficiently heated – check the tank temperature and required melt temperature of your adhesive and set accordingly.

- Inadequate or no input air to pump – increase the air pressure from the plant air supply and see if the pump will run.

- Dry running – when a tank drops below a certain adhesive level in the pot, the pump does not have enough glue to operate at full capacity. The glue that runs through the pump acts as a padding so that the shifter does not pound against the top and bottom of the pump itself. When that padding is less, the pounding shifter can cause damage to the magnets and create an issue with the shifter. The only solution to this is to get a new shifter and potentially invest in an auto fill on-demand system that fills the glue into the tank for you, leaving less pressure on the line operators to fill the pot.

- No Tank Screen or Clogged Tank Screen – the tank screen lives at the bottom of the tank and is the first line of defense against any foreign debris getting into the pump. Sometimes the tank screen gets removed or never cleaned. That can cause debris build up and seize your pump. It is easily cleaned by lifting out of the empty tank and then cleaning the tank with Purge Plus™.

- Clogged Tank Filter – the tank filter screws into the side of the tank and filters the glue after it leaves the tank. If the tank filter is clogged, then the adhesive will back up in the pump, causing the pump to seize.

- Pump solenoid is not on – if the tank is not within 35 degrees of the setpoint temperature on the control panel, the pump solenoid will not turn on. Check the setpoint temperature and make sure it is correct. If the setpoint temperature is correct and reading properly, then it might be a failed solenoid that needs to be replaced.

If you go through all of these troubleshooting steps and still have an issue with your pump, please call (561) 272-5442 or email sales@ussefl.com.

How to Prevent Your Glue from Stringing

One of the most common issues that many packaging line operators experience with their adhesive melter is stringing. Stringing is when the adhesive is applied to the box, but before the flaps are closed on the cartoner, the glue starts to dry and string like cotton candy floating through the air.

There are a couple of fixes for this issue. Whether you are using a straight, right angle or swirl pattern nozzle, try moving the applicator gun closer to the box flap where you are applying the adhesive. The stringing could be caused because it is travelling too far of a distance from the applicator gun to the box. The shock from hitting the cooler factory air could be causing it to lose viscosity and start drying before it even hits the box. Not only will that cause stringing, that might also compromise the integrity of the glue hold on your product packaging.

Another cause of stringing glue could be temperature. Every adhesive is different and each one might require a different melt temperature. In order to keep the adhesive a consistent viscosity, make sure that the temperature on your glue tank and applicator guns are set correctly per the adhesive requirements. If the adhesive is too viscous then you might need to increase the tank temperature or change to an adhesive with a lower viscosity. If your tank temperature is correct, but your guns are not hot enough, then the glue could start to cool while travelling from the tank to the applicator gun. In this scenario, you would see that the thickness of the glue as it leaves the nozzle. Some line operators might try fixing the issue by putting a larger diameter nozzle on the module, which could be a temporary fix, but the real issue could be the temperature setting on the gun. Simply increase the gun temperature as needed to ensure a smooth, consistent adhesive flow.

There could also be an issue with the adhesive you are using on your packaging line. Like many products, if the adhesive is too old, has been sitting for too long, or has been heated and cooled too many times, this could cause stringing. We recommend that you drain all old adhesive from your tank, clean the tank with a cleaner such as Purge Plus™, and refill with fresh adhesive.

Universal Systems SE recommends trying to correct stringing if it is happening to your packaging line. Some line operators may think it is not that big of an issue, or they might blame the adhesive manufacturers, when in fact it could be a simple and important fix.

For more information or technical support to help you better understand how to fix your stringing glue, please call Universal Systems SE at (561) 272-5442 or email sales@ussefl.com.

A Personal Touch

Are you tired of listening to an automated phone system prompting you through a series of directories just to get someone on the phone? Then, after 20 minutes you still get sent to an operator and have to leave a message. At Universal Systems SE, that definitely will not happen. We pride ourselves in the personal relationships that we build with our customers. You will always have a direct sales representative that can help you with quotes and orders, or that will put you in touch with a technician or engineer that can help with any operation related inquiries.

Easy Online Quotes

If you would rather get a formal quote than speak to a sales representative, our website offers easy online quote forms for all of our products. Simply search for the product that you need, or the cross-reference number you may have, in the search box at the top right of our website. Then fill out the custom online quote form. An email will be sent directly to a sales representative who will get back to you within a couple of hours with a formal price quote. It’s quick and hassle free.

Instructional Videos

Universal Systems SE also offers several instructional videos on our YouTube channel. You can watch Meredith and Chris explain how an adhesive melter works, how to set your melter temperature, and even an introduction to the newly launched ProBilt® Phoenix on-demand melter system.

Order Confirmations

At Universal Systems we always want to make sure that you know when your order ships with an estimated time of delivery. At the end of each day, all of our order shipment confirmations get emailed out with your UPS or FedEx tracking numbers. This way you are never left wondering when you are going to get your products.

These amenities add value and a personal touch that not every company in the packaging industry offers. To create your own personal working relationship with Universal Systems, call us today at (561) 272-5442 or email sales@ussefl.com.

A Class Above the Rest

There are five main components that should go into your search for the right hot melt equipment manufacturer: Innovation, Knowledge, Quality, Price & Compatibility. Universal Systems SE has made it our top priority, over the last four decades, to ensure our customers get all of these. We do not compromise price for service and we stand behind all of our equipment with the strongest warranty program in the industry.

Innovation

Universal Systems SE has just launched our latest product in the ProBilt Series: The ProBilt Phoneix. This on-demand melter system allows packagers to melt and use adhesive only when they need it. The adhesive storage container eliminates the need to manually fill the melter tank, reducing adhesive spillage and waste, while improving safety. Our state of the art adhesive sensor and innovative vacuum technology will automatically fill your tank with adhesive to your desired level.

Universal Systems SE also manufactures 8 lb., 12 lb., 15 lb., 20 lb. and 40 lb. tanks that are the same footprint as most Nordson melters on the market. Our ProBilt systems continue to lead the industry with minimal down-time, easy to operate components and consumer flexibility.

Knowledge

When researching manufacturers to partner with, knowledge and availability are key. Our technicians have over 40 years’ experience in the hot melt industry and can help solve almost every issue you might run in to, because we have seen it all! Universal Systems SE’s facility is located in the United States and we are available for service calls, even if it’s a video conference to walk through any issues you might be experiencing.

Warranty, Price, Compatibility

We stand behind all of our products 100%, which is why we offer the longest warranty in the industry on our ProBilt tanks, 10 years! Also, if you find a cheaper rate from another direct manufacturer, which we are confident you won’t, we will match that price! Whether the pricing is from Nordson, Graco, ITW Dynatec or Robatech. We also ensure that almost all of our equipment is Nordson compatible. This means that even if you bought your main hot melt machine from Nordson you don’t have to stay with them forever. Even if your Nordson melter has been discontinued, such as the 2300 or 300 Series, you can still buy all of your replacement parts from USSE. We will warranty all parts that you buy from us, even if they are being paired with a competitor part.

For more information on Universal Systems SE or the ProBilt Series, please contact us at (561) 272-5442 or email us at sales@ussefl.com.